Engineering Plastics

Technical plastics represent about 20% of the worldwide plastic production. The characteristics of these materials exceed those of standard plastics which leads to a higher price.

The use of technical plastics is not for optical or haptic purposes, but only for technical usage.

Technical thermoplastics are usually be able to bear temperatures up to 130°C. They are particularly characterized by high durability, good viscosity and shock absorption as well as a usually good processing and a balanced cost-benefit relation.

Technical plastics (PA, POM, PC) are used for all application types. As a result, slide bearings, rollers and wheels or sealings as well as formed parts, isolators or housings and workpiece supports are made of these materials.

Many traditional materials like metal components are more and more replaced by high-quality plastics because of their known advantages like: good abrasion resistance, no corrosion, excellent sliding characteristics, high durability, good chemical resistance, dimensional stability as well as high temperature stability.

(no guarantee for any information given)

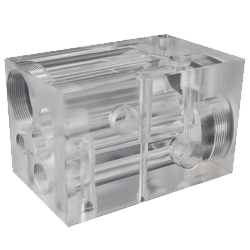

POM (Polyoxymethylen)

Milled part from POM

POM is used as technical plastic material especially for precision parts due to its high rigidity, low frictional coefficient and excellent dimensional stability.

Difference is made between homopolymeres (POM-H) and copolymeres (POM-C). Because of their higher crystallinity the homopolymered have a little higher density, hardness and stability. In contrast, copolymeres have a higher impact resistance, better abrasion resistance as well as better thermical and chemical stability.

- high stability, rigidity and hardness.

- good impact resistance even with low temperatures

- less humidity absorption (with 0,8 % saturation)

- good creep resistance

- high dimensional stability

- resistant to hydrolysis (up to ~60 °C)

- good size accuracy

- resistant to wear and tear

- very good resilience

PA (Polyamid)

PA6 flange

Polyamides are partially chrystalline. Synthetic polyamides have a high stability, rigidity and a very good chemical resistance. Furthermore, they have a high war and tear resistance and good sliding properties. The mechanical qualities can be adjusted easily by using fibre compounds with glass or coal fibres and, hydrolysis can be reduced. Also the relatively high water absorption of up to three percent by mass can be reduced.

- Good mechanical stability

- High impact resistance

- Good shock absorption

- Good sliding characteristics

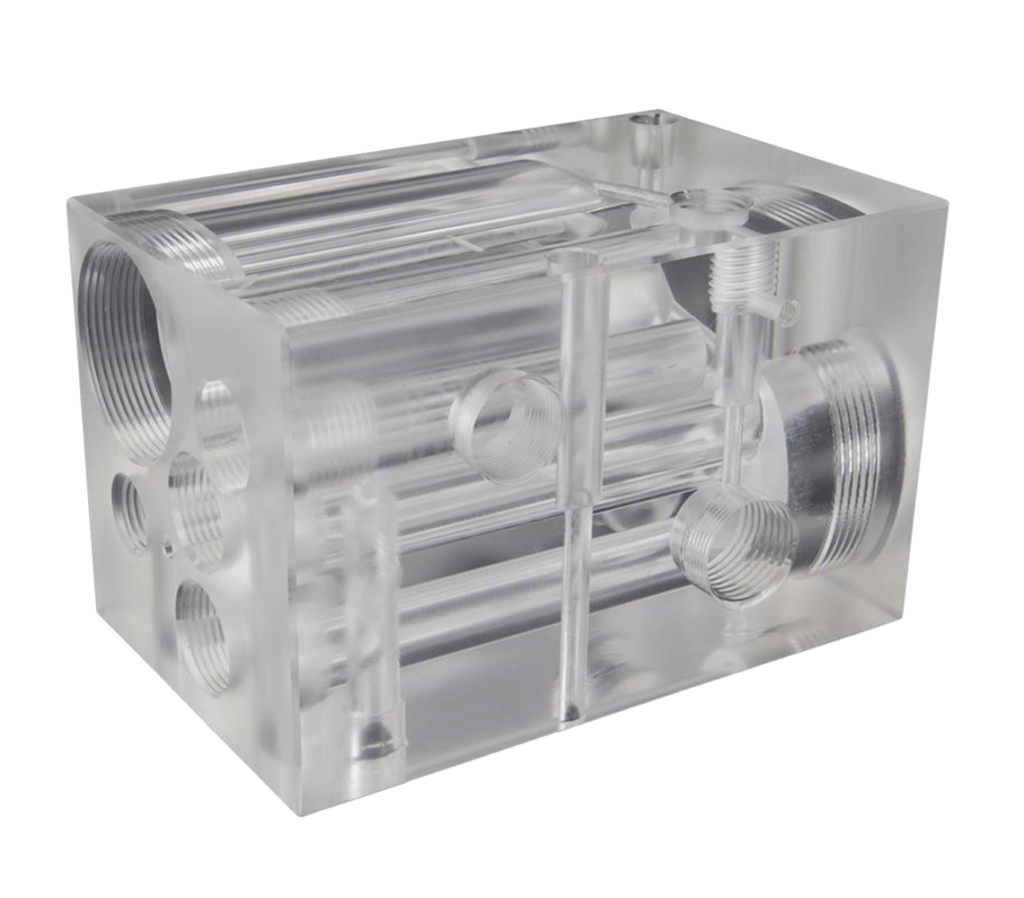

PC (Polycarbonat)

Distributor from PC

Polycarbonates are crystal clear, can be dyed, welded and glued and they have a high dimensional stability as well as impact resistance.

- High mechanical stability

- Very good creep resistance

- Very high impact resistance even at low temperatures

- Rigidity is kept within a wide temperature range

- Very high strength in shape

- Very good resistance to wheather conditions

- Good electrical insulation capability

Contact

Address:

1Tecoplast GmbH

Schlattweg 10

72178 Waldachtal

Germany

E-Mail: info@tecoplast.de

Phone:+49 7486/979035

Fax: +49 7486/979059