High performance plastics

Just about 0.2% of the worldwide plastic production belong to the category of high-performance plastics. Depending on the application, one or several characteristics of these materials are clearly optimized.

Usually, high-performance plastics are distinguished from technical plastics by means of the continous operating temperature. Usually technical thermoplastics can be used at a temperature of 130°C, whereas high-performance plastics can be resist to temperatures of over 150°C permanently.

These materials can also be called high-temperature plastics. However, these materials resist to considerably more than just high operating temperatures. Some of them also endure cryogenic conditions with temperatures below minus 200°C, others are extremely resistant to chemicals, radioactive radiation or other impacts. Other characteristics of high-performance plastics can be extraordinary resistance to wear and tear, high purity or particular electrical insulation. Due to these particular characteristics, high-performance plastics can be found in the higher price segment.

(No guarantee for any information given)

PVDF (Polyvinylidenfluorid)

PVDF ring

PVDF is used as inner coating for pipes or exterior components as a result of its good thermical and chemical resistance. As this material type can be produced in ultrapure environment, it is used in chip manufacturing (micro electronics) and for pipe systems for the transport of ultrapure materials like high-purity water.

– high continous operating temperature (140 °C)

– no water absorption

– good dimensional stability

– high chemical resistance

– good resistance to hydrolysis

– weatherproof

– stable to radiation

– good electrical isolator

– high abrasion resistance

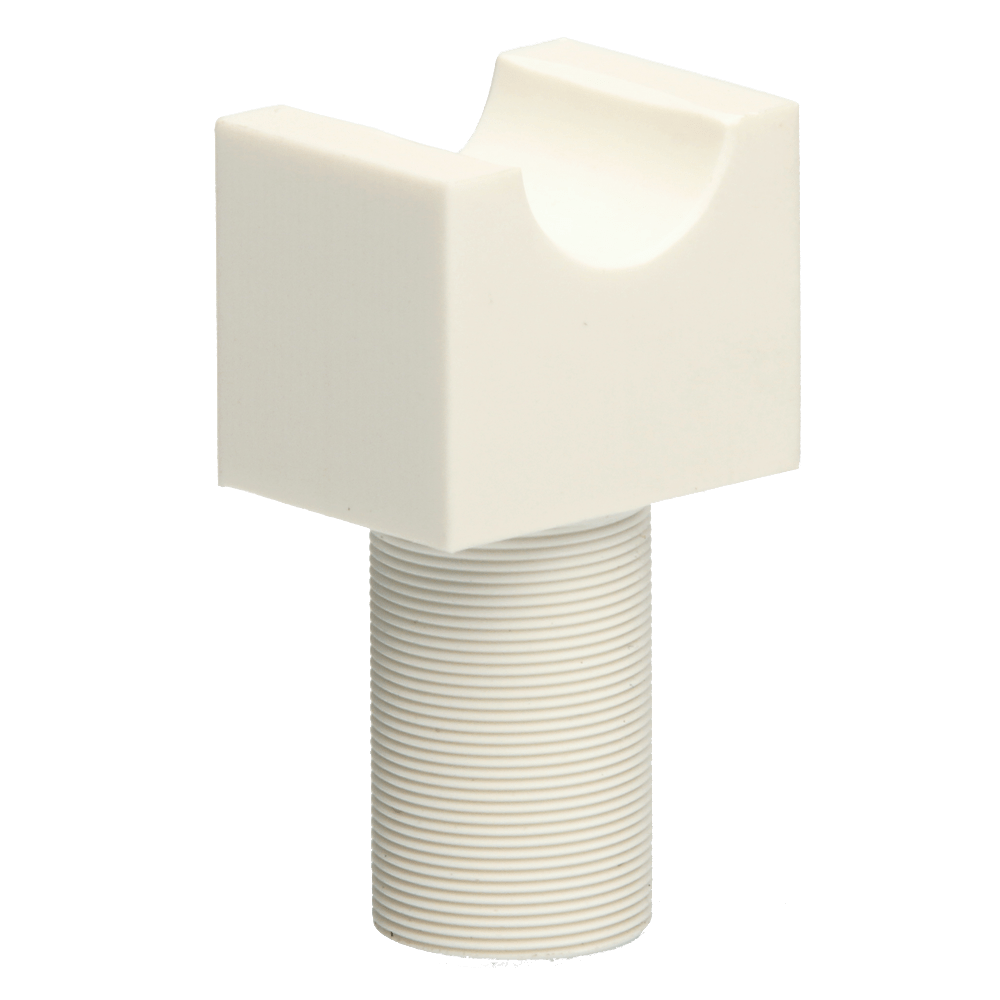

PTFE (Polytetrafluorethylen)

Milled part made of PTFE

PTFE is very sluggish in reaction. Even aggressive acids like nitrohydrochloric acid are not able to attack PTFE. As the frictional coefficient is very low PTFE slides on PTFE as good as wet ice on wet ice. Moreover, the sticking friction is the same as the slide friction, thus, changeover from standstill to movement happens without any jerking.

Hardly anything is able to stick on PTFE as its surface tension is extremely high.

– Density: 2,2 g/cm³

– stable to all acids and bases

– not resistant against natrium

– Operating temperature up to 260 °C (in case of temperatures over 400 °C, extremely toxical pyrolysis products, e. g. fluoric phosegene are evaporated)

– frost-resistant up to -200 °C

– only adhesive after pretreatment

– physiologically harmless

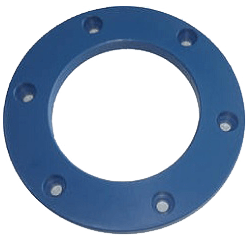

PPS / PPSU (Polysulfone)

PPS flange

Polysulfones are characterized by high consistency, rigidity and durability and those properties are even kept at temperatures between −100 und 150° C. The dimensional stability is very high, however, volume of the material changes when getting in touch with cooking water or hot air (temperature of at least 150 °C) or if the air humidity falls below 0,1 %.

– good resistance to chemicals

– resistant to mineral acids, bases and electrolytes

– not resistant to ketones and chlorinated hydrocarbones

PEEK (Polyetheretherketon)

PEEK part

Polyetheretherketon resist to nearly any organic and anorganic chemicals. They also resist to hydrolysis up to a temperature of approx. 280 °C. However, they are not resistant to UV radiation, concentrated nitric acid and some halocarbones.

– flame-resistant

– high resistance to chemicals

– high stability under high temperature

– high consistency

– high dimensional stability

– resistant to wear and tear

– good slide and friction characteristics

Contact

Address:

1Tecoplast GmbH

Schlattweg 10

72178 Waldachtal

Germany

E-Mail: info@tecoplast.de

Phone:+49 7486/979035

Fax: +49 7486/979059