Standard plastics

Standard plastics represent about 80% of the worldwide plastic production. These materials are especially optimized with regard to a favourable manufacturing.

They are particularly used for bulk applications in the packaging and consumer goods industry and, above all, for optical purposes. Its mechanical characteristics are clearly behind those of the technical plastics. Nevertheless, standard plastics partly have unique qualities making them the first choice for special technical applications. Especially due to the high resistance to chemicals of polyolefines (PE, PP) or the good insulation qualities of PVC, these standard plastics are eligible for specific technical applications.

Pipe and container construction are typical application areas for standard plastics. They are also utilized for mechanically less-strong loaded applications or electrical insulations.

(no guarantee for any information given)

PVC (Polyvinylchlorid)

PVC cap

PVC is hard and rough, but by adding softeners and stabilizer the durability and viscosity of PVC can easily be diversified and the material can be dyed as well. PVC picks up hardly any water and is stable to acids, bases, ethanol, oil and gasoline. PVC can be attacked by acetone, ether, benzol, chloroform and concentrated hydrochloric acid. It is possible to create connections with glue (solvent glue, two-component glue) or by welding (different manual and automatic welding processes).

- optimally suitable for container and appliance construction

- chemically resistant

- high rigidity

- stable to UV radiation and wheater conditions

PE (Polyethylen)

PE closure cap

PE provides a good eco-balance. Polyethylene is resistant againt acids, bases and further chemicals. A disadvantage is, that PE cannot be used at temperatures over 80 °C. Non-dyed PE is milky unclear and dull. It feels like wax and can be scratched.

PP (Polypropylen)

PP plastic container

With a density between 0,895 g/cm³ and 0,92 g/cm³ PP is the lightest of all plastics. Polypropylene is the second important plastic material with 20% of the total production. Even though polypropylene is relatively similar to the chemical construction of PE, it is clearly harder, more solid and more stable to temperatures.

- Through the glass transition temperature of 0°C, it gets rough with cold temperature. The highest operating temperatures are between 100 and 110°C.

- Resistant to alcohol, organic solvents and greases.

- Not resistant to gasoline, benzol and hydrocarbons.

- Odorless and gentle to skin

- Suitable for applications in the food and pharmacy industry.

- Physiologically harmless

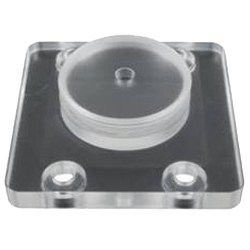

PMMA (Polymethylmethacrylat, Acrylglas)

Milled part from PMMA

- Excellent optical characteristics

- Very high translucence and highest brillance of all plastics

- High rigidity and dimensional stability

- Durability and highest scratch resistance of all plastics

- Excellent resistance to wheater conditions, UV radiation and deterioration

Contact

Address:

1Tecoplast GmbH

Schlattweg 10

72178 Waldachtal

Germany

E-Mail: info@tecoplast.de

Phone:+49 7486/979035

Fax: +49 7486/979059