Welcome at 1TECOPLAST,

Your specialist for turning, milling and welding plastics

Our service

Customer satisfaction is the most important thing

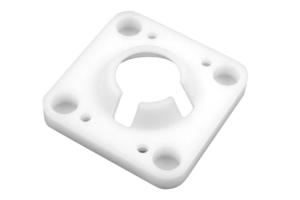

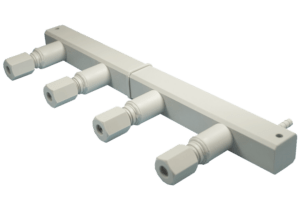

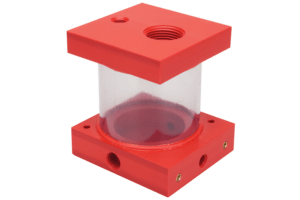

The specialist for turning, milling and welding plastics. 1TECOPLAST is a medium-sized company that is working since 1997 with motivated employees and precision CNC-machines on economic solutions in the processing of technical precision parts out of thermoplastics.

1TECOplast – We are partner in production of semi-finished- and finished parts of precision parts out of plastics for many industrial sectors. We produce your requirements individual according to drawing or sample out of technical plastics with CNC-controlled machines and CAD-CAM assistance in the process turning plastics and milling plastics.

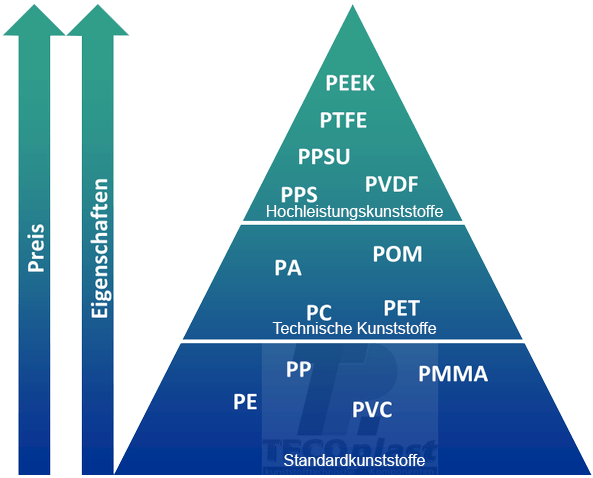

1TECOplast – We use all high-quality thermoplastic polymers that are available on the half-finished products market, like PE, PP, PVC, PA, PSU, POM, PVDF, PEEK, PMMA, PTFE and all other high-quality plastics as well as fiber-reinforced plastics in all cutting processes. We are absolutely familiar with the assembly of structural components, as well as the bonding, joining and welding of containers, modules and pipes.

1TECOplast – With optimized production processes we are producing prototypes, small series and series in numbers of thousands. We deliver speciality goods that relate the high measurable requirements on quality and precision. Flexible, economic and dependable with precision. This is guaranteed by the expertise of our staff.

1TECOplast – The quality management comply with the requirements of the customers and is certified since the year 2000 with DIN EN ISO 9001:2008. The business policy is consequent orientated on the requirements of the customers regarding service, quality, competitiveness and customer satisfaction.

TECOPLAST: partner for these industrial sectors

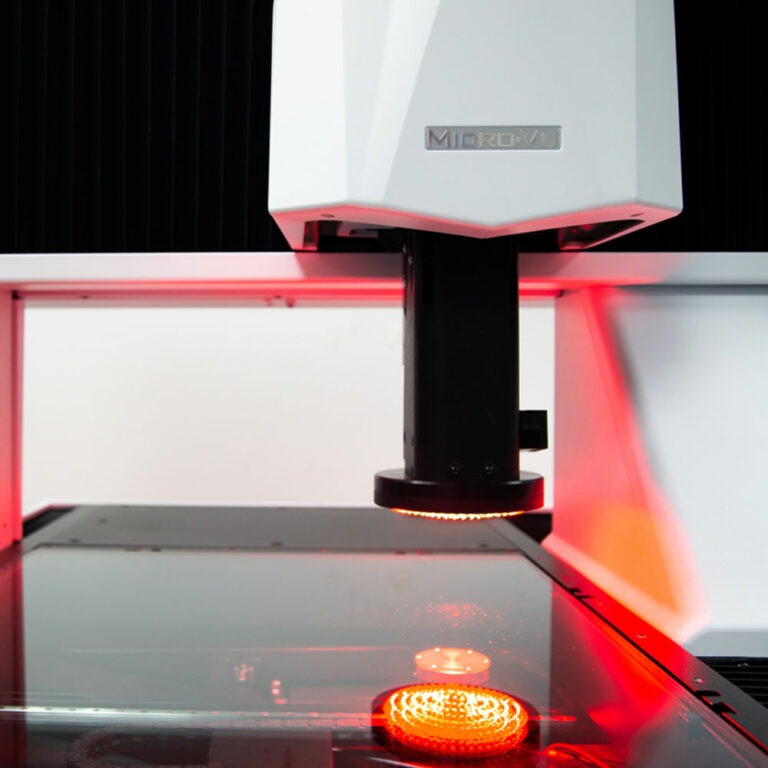

Precision parts off plastics – quality control

Higher quality standard

May it be a little more precise?

With each and every manufacturing job and measurement of our plastic precision parts, our qualified staff are aiming at optimizing the production processes by permanent error prevention, in order to exceed the quality requirements established by the current general DIN EN ISO 9001:2008 standard.

Under certain circumstances we can provide the following documents (partly with costs):

Confirmation of the ROHS / REACH compliance

Initial sample Inspection Report

Long-term supllier´s declaration

Factory certificate according to DIN EN 10204

Our quality management system is supported by a new ERP and PPS system.

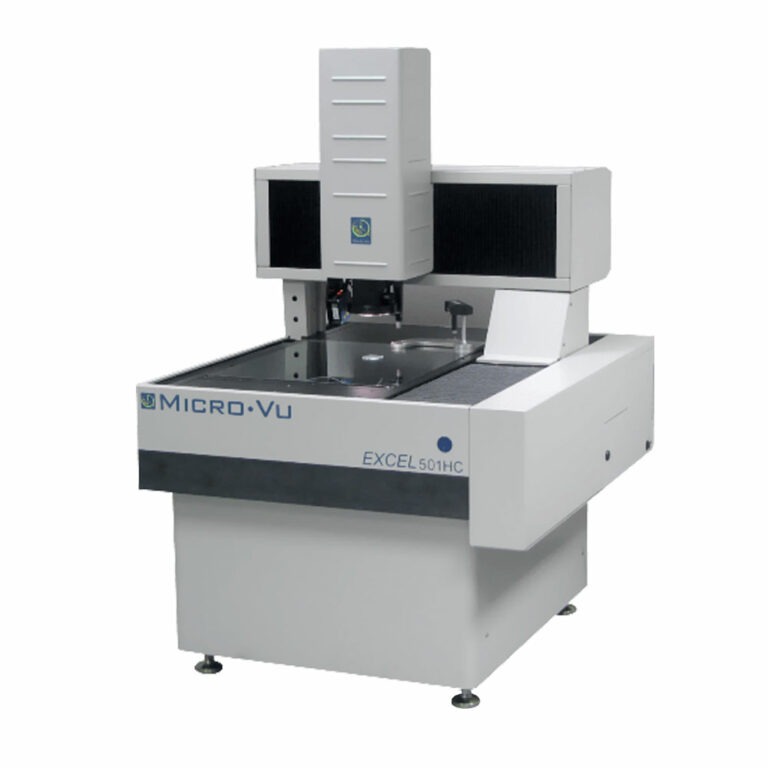

We use the most modern measuring instruments, such as optical calibration units and 3D coordinate measuring systems, to measure and verify specified dimensions and tolerances of diverse threads, drillings, edges, etc.

You can download our current quality management certificate here.

Plastics

Since a while plastic materials have become more and more important in all industries because of their characteristic profile. Compared to metal materials, their inner composition is basically different which is the reason for the lower mechanical and thermical stability.

Plastic materials have one extraordinary property: by choosing different basic materials and processing ways and by adding additives, their technical characteristics like plasticity, durability, elasticity, rupture strength as well as thermical and chemical resistance can be diversified in a wide range.

The essential lower weight, by comparison to other materials like metals or ceramics, and the excellent working properties argue for the use of modern plastics.

Raw material overview

Contact

Address:

1Tecoplast GmbH

Schlattweg 10

72178 Waldachtal

Germany

E-Mail: info@tecoplast.de

Phone:+49 7486/979035

Fax: +49 7486/979059