Milling plastics

Production informations for milling plastics

Plastics show a lot of advantages compared to metals like less weight, good slip characteristics, reliability against chemicals and a lot more. Therefore plastics and the plastic processing generally are more and more important for the technics. Milling plastics is an important area of processing plastics and there are some points that should be considered. Plastics have a considerably less heat conductivity as metals, that means the arising heat at the cutting needs to be leaded away over the chips. With the choice of the right tools and the right cutting parameters you can strongly impact the heat input into the material. Also the right tensioning of the raw material is deciding. A too strong tensioning can deform the material in the bench vice, what will cause a variation in dimension after the production because the material expands again after removing.

The economic production of complex technical plastic milled parts:

- Single or series production

- Visual, electronic and 3D- measuring systems

- Latest CNC-technology

- max. length: 1035 mm

- max. width: 600 mm

- milling plastics from the specialist

Materials

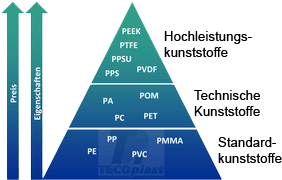

There are many plastics on the market, some of which differ significantly in their properties and price. The properties of the plastics can be further improved with additives such as glass fiber, oil or carbon fiber. We process all common thermoplastics such as PE, PP, PVC, POM, PA6, PA6.6 GF30%, PTFE, PVDF, PEEK, and many more.

Tools

The right tool and the right cutting speed is very important in plastic processing.

It should be chosen a sharp milling tool because a stump milling tool can lead to the melting of the plastic and unclean cutting edges. A sharp milling tool can bring less heat into the component because of its good cutter. A high cutting speed improves the surface of the milled part because less heat comes into the part. This is because the chip will be rather teared off than cutting cleanly at lower cutting speed.

Examples of milled parts

Contact

Address:

1Tecoplast GmbH

Schlattweg 10

72178 Waldachtal

Germany

E-Mail: info@tecoplast.de

Phone:+49 7486/979035

Fax: +49 7486/979059